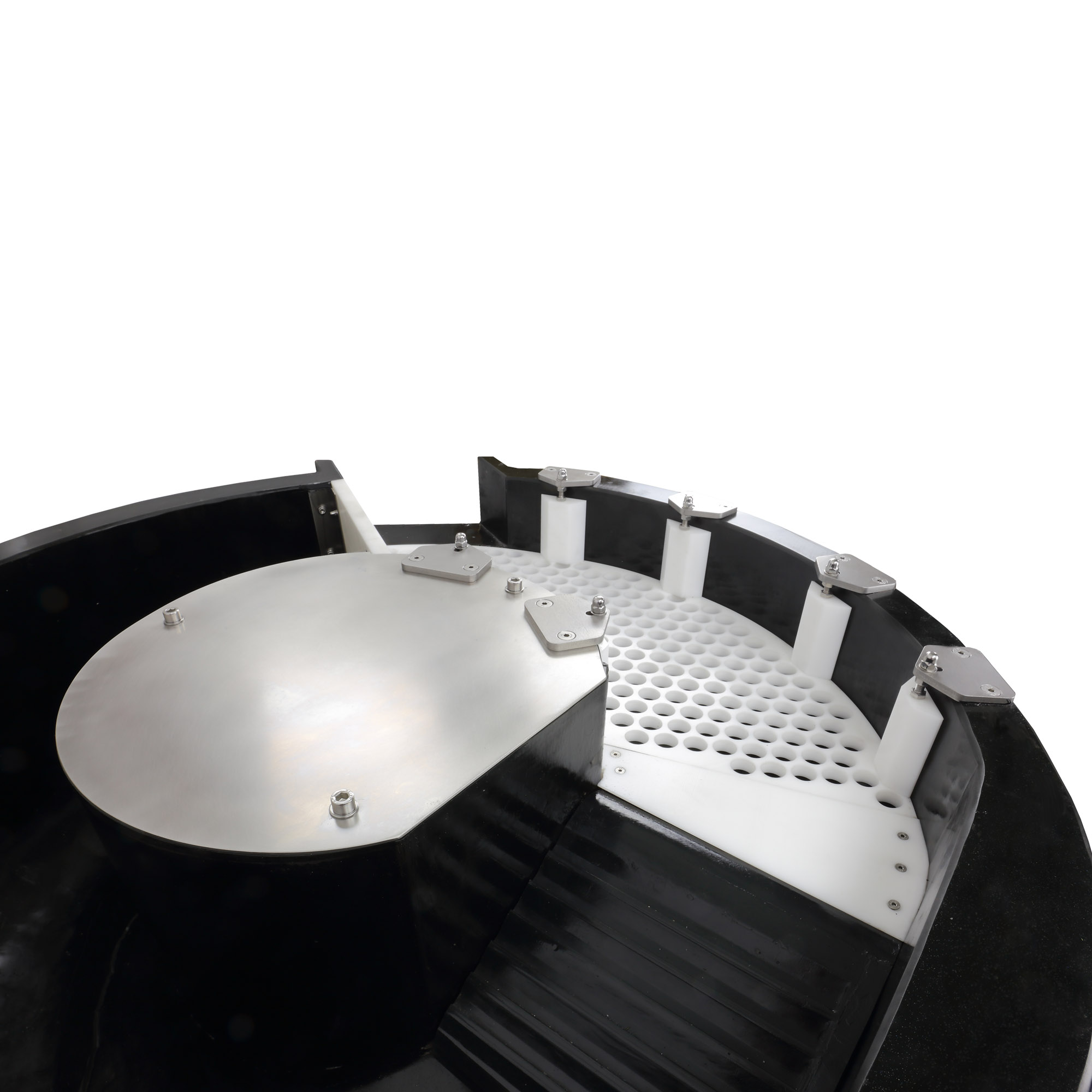

Round vibratory machine WGS250

CATEGORIES:

-

Disc finishing machines

- Disc finishing machine TE18x3

- Disc finishing machine TE18x2

- Disc finishing machine TE10x3

- Disc finishing machine TE10x2

- Disc finishing machine TE60

- Disc finishing machine TE30

- Disc finishing machine TE18

- Disc finishing machine TE10

- Disc finishing machine TFS30

- Disc finishing machine EC10

- Disc finishing machine EC6

-

Trough vibratory machines

-

Round vibratory machines

-

Separating units

-

Process water

-

Dryers

-

Media

Advantages

- suitable for deburring, edge rounding, descaling, degreasing, matting, rough and final grinding

- enables processing using ceramic and plastic chips

- stand-alone version with a stable, robust construction

- integrated, mechanical separation of workpieces from the abrasive charge

- bottom of the working chamber with a snaily driveway

- discharge plug enabling quick and convenient emptying of the working bowl

- possibility of smooth speed control

- safe and gentle treatment of fine workpieces, no impingement each other

- simultaneously processing workpieces with different wight, size and geometry

- process recurrency, homogeneous results on a surface

- reliability and durability- polyurethane lining of the working bowl is extremely wear-resistant (8-times higher than steel)

Items included

- Round vibratory machine WGS250 with cable to connect the selected control panel

Optional accessories

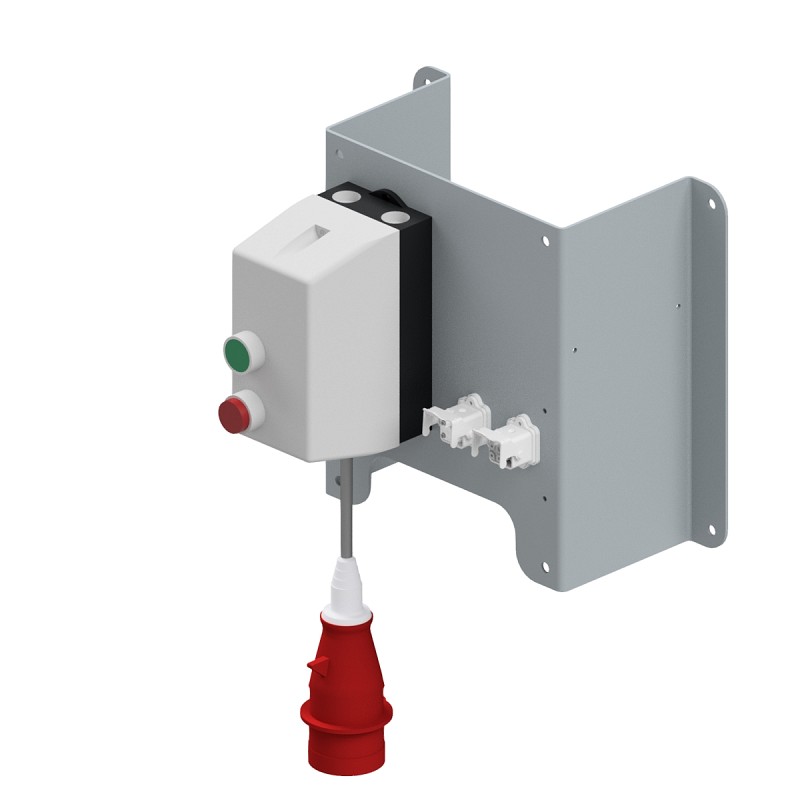

START/STOP switch (3×400 V)

Control panel with smooth speed regulation and timer

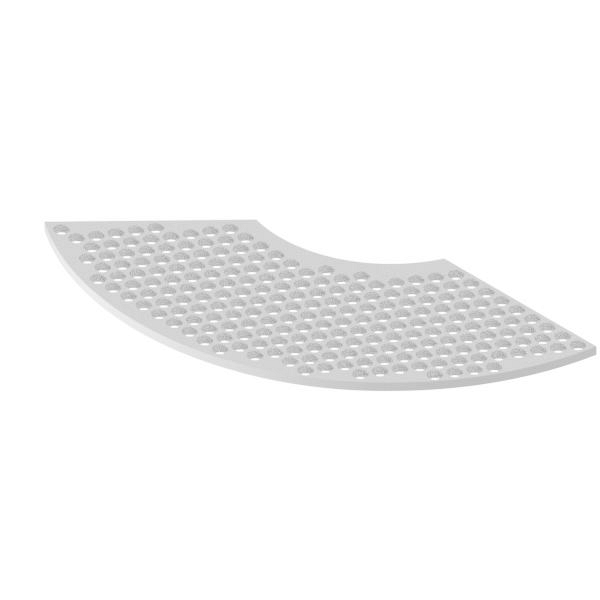

Selected sizes of separator sieve

Dosing pump

Stainless steel stand for control panel

Sound dampending, freestanding lid