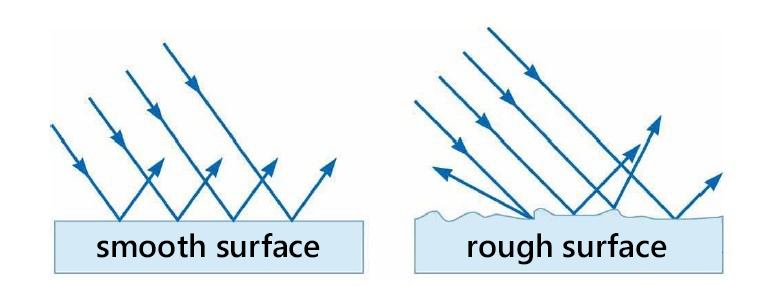

How mirror-like the surface of a given object is depends on the degree and angle of light reflection. If light falls on a rough surface, it falls at different angles and is therefore reflected in many different directions, i.e. dispersed.

Light falling on a smooth surface, on the other hand, is reflected in the same direction and the reflections are still parallel. This is why we are able to see an image in the mirror that so faithfully reproduces every detail of the object.

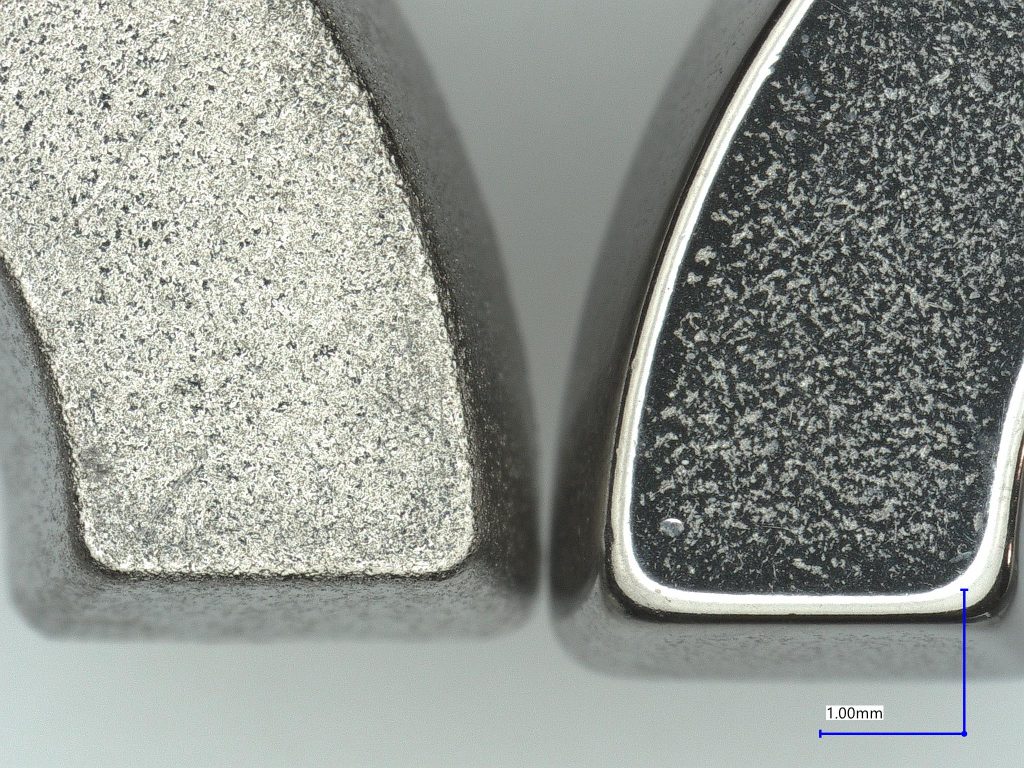

Hence, it is easy to conclude that in order to obtain a shiny surface, it must be smoothed as much as possible. Therefore, in the process of polishing jewelry, the key to success is the stages preceding the final stage – polishing itself, i.e. grinding and smoothing.

The above photo shows a magnified view of a very rough surface that could not be completely smoothed, so the polish will not be mirror-like.

Here, the ring surface was suitably prepared in a disc finishing machine and thus after polishing it achieved a mirror shine.