Disc finishing machine TE60

CATEGORIES:

-

Disc finishing machines

- Disc finishing machine TE18x3

- Disc finishing machine TE18x2

- Disc finishing machine TE10x3

- Disc finishing machine TE10x2

- Disc finishing machine TE60 ECO

- Disc finishing machine TE60

- Disc finishing machine TE30

- Disc finishing machine TE18

- Disc finishing machine TE10

- Disc finishing machine TFS30

- Disc finishing machine EC18

- Disc finishing machine EC10

- Disc finishing machine EC6

-

Trough vibratory machines

-

Round vibratory machines

-

Separating units

-

Process water

-

Dryers

-

Media

Advantages

- designed for mass finishing of small workpieces (up to 10 kg at one time)

- available for wet (TE60 W) or dry processing (TE60 D)

- automated system of unloading the working bowl

- TE60 WET enables deburring, rounding edges, degreasing, removing burrs, cleaning, mattifying, grinding, smoothing and finally polishing

- wet processing with plastic chips, porcelain as well as stainless steel shots

- TE60 DRY enables smoothing and polishing of different materials with walnut shell or wooden blocks in combination with grinding and polishing pastes

- solid steel construction with an integrated system for separating workpieces from the media

- the biggest disc finishing machine available

- optimized media movement and excellent processing results due to curved flow-optimized design of the working bowl

- processing of very thin pieces and trouble-free maintenance through use of a very precise gap system (0,05 mm upwards)

- toroidal movement prevents workpieces from sticking to each other

- tilted working bowl for easy unloading

- reliability and durability – polyurethane lining of the working bowl is extremely wear-resistant (8 times higher than steel)

Items included

- Disc finishing machine TE60 according to a chosen configuration

- 2x control panel with timer and frequency inverter

- Dosing pump (according to configuration)

- Air pump (according to configuration)

- Compound level sensor with compound tank (according to configuration)

Optional accessories

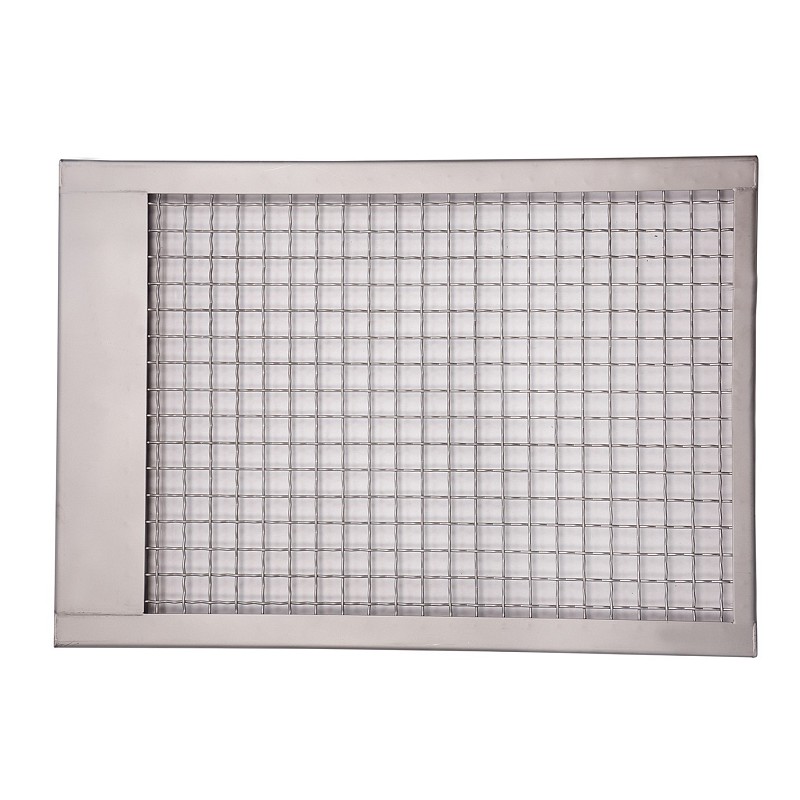

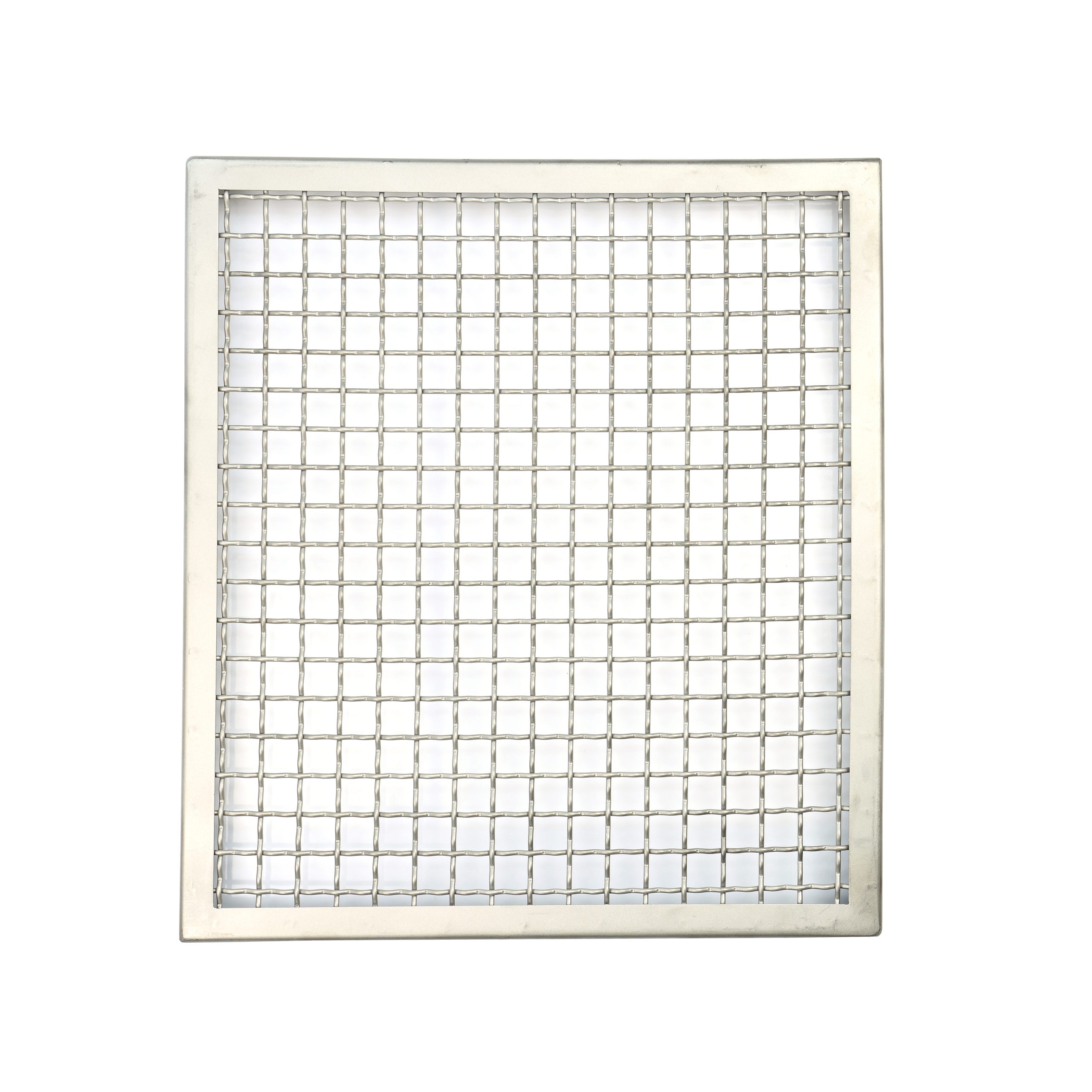

Manual separation unit (without sieve)

Mechanical separation unit TESEPA

Stainless steel sieves

Stainless steel sieves for separation system TESEPA