Anodizing, chrome plating and other coatings

Manufacturing parts is currently just one of the stages of the entire production process. In addition to giving them their final shape in accordance with the specification, products made in this way are often subjected to additional surface treatment processes.

Obtaining a durable coating on parts subjected to nickel plating, chrome plating, anodizing or powder coating depends to a large extent on proper surface preparation. Only the surface of the object free from surface contamination (such as rust and scale), free from burrs and sharp edges and having the appropriate roughness allows for obtaining durable decorative and protective coatings.

The vibro-abrasive processing with appropriately selected abrasive media allows for meeting the above requirements.

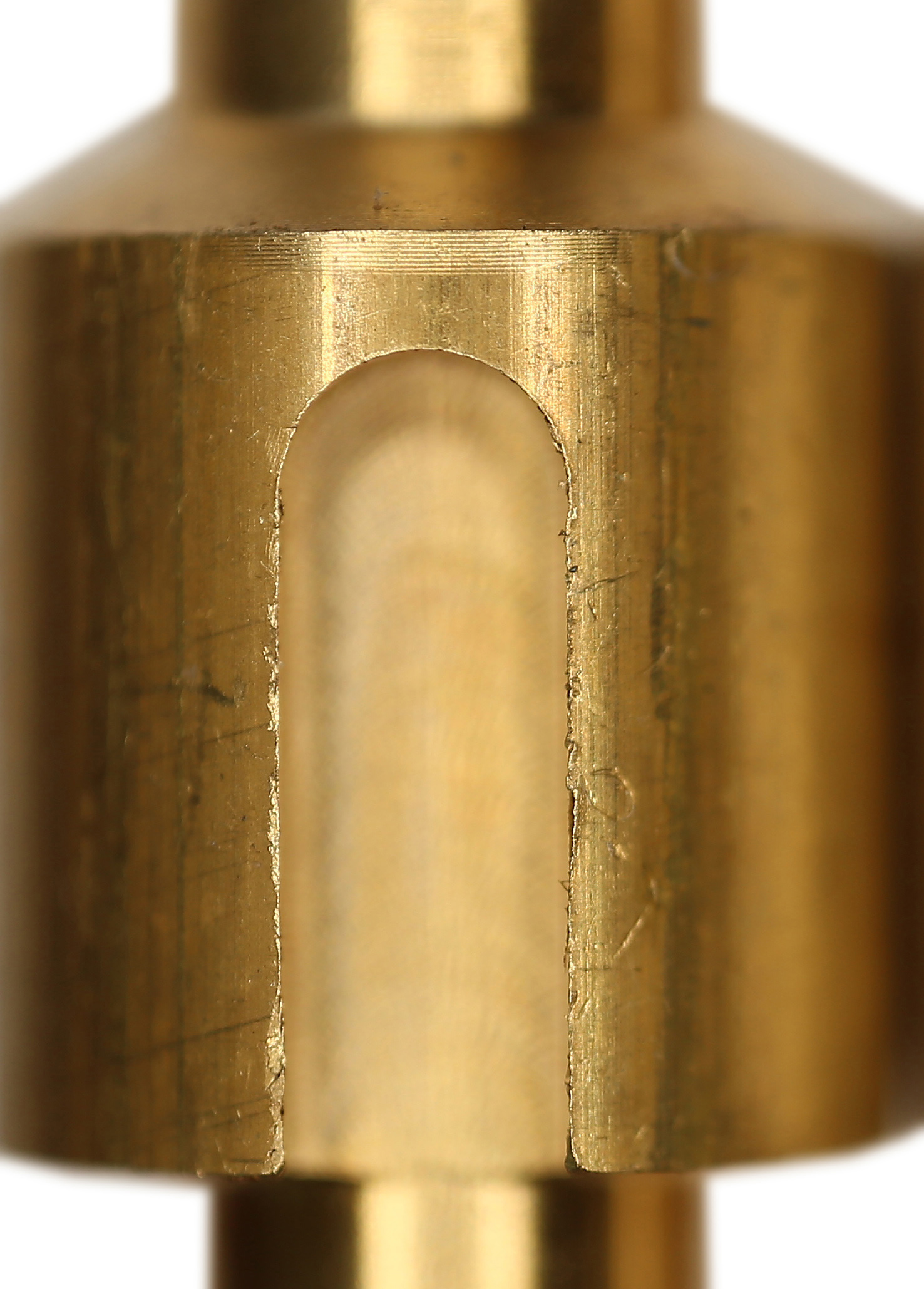

Examples of processing:

Send your samples

and see the result.

Sample form