Laser-cutting

Elements after laser, plasma or water jet cutting often have sharp edges, and their surface is often covered with burns. Blunting sharp edges and removing oxides from the surface of the material improves the aesthetics of the products and ensures safety when working with the material.

A properly selected machine guarantees high processing efficiency and achieving the desired surface condition – from removing burrs and excess to smoothing the surface. Quick removal of sharp edges is achieved in the deburring process in disc finishing machines, or due to larger dimensions in round or trough vibrators.

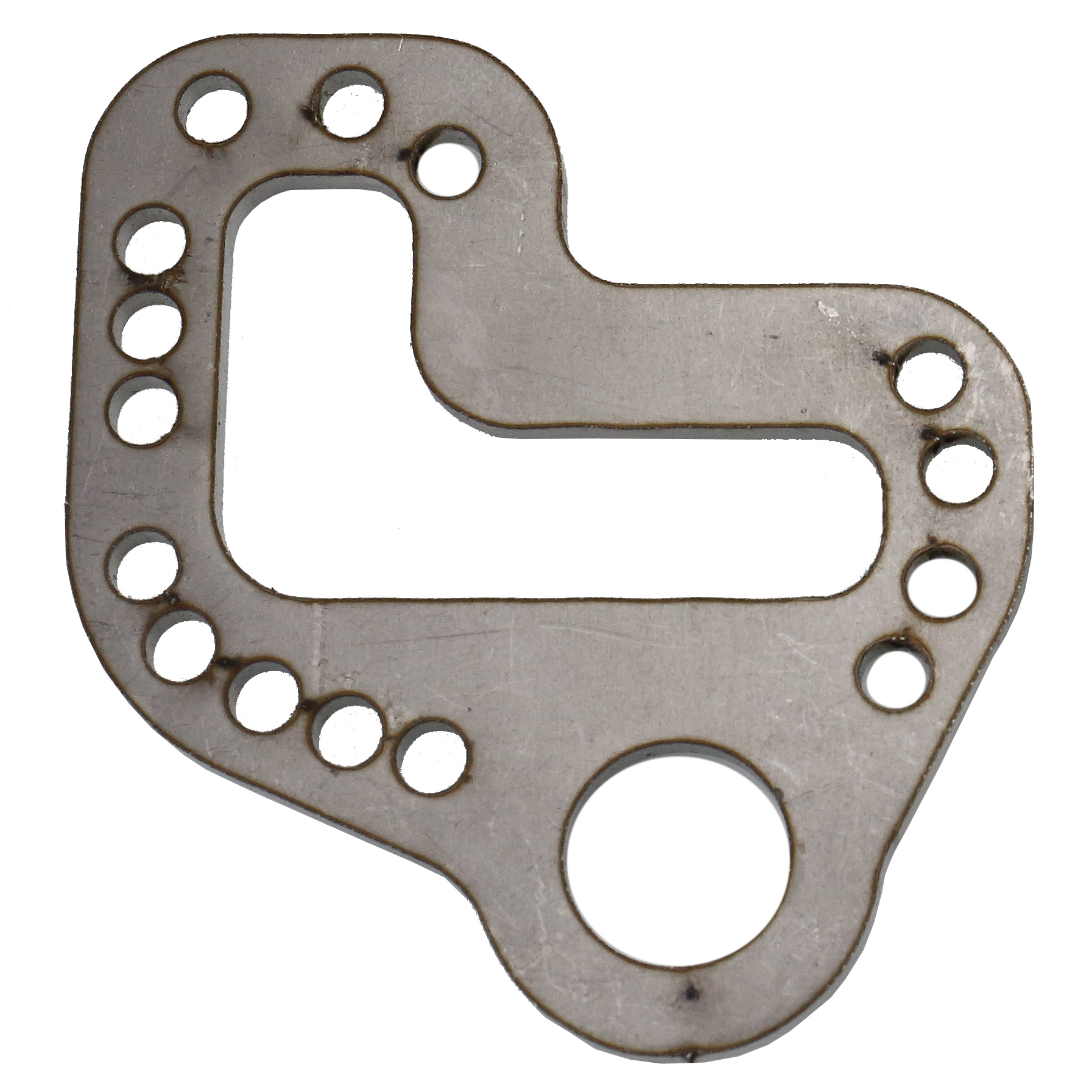

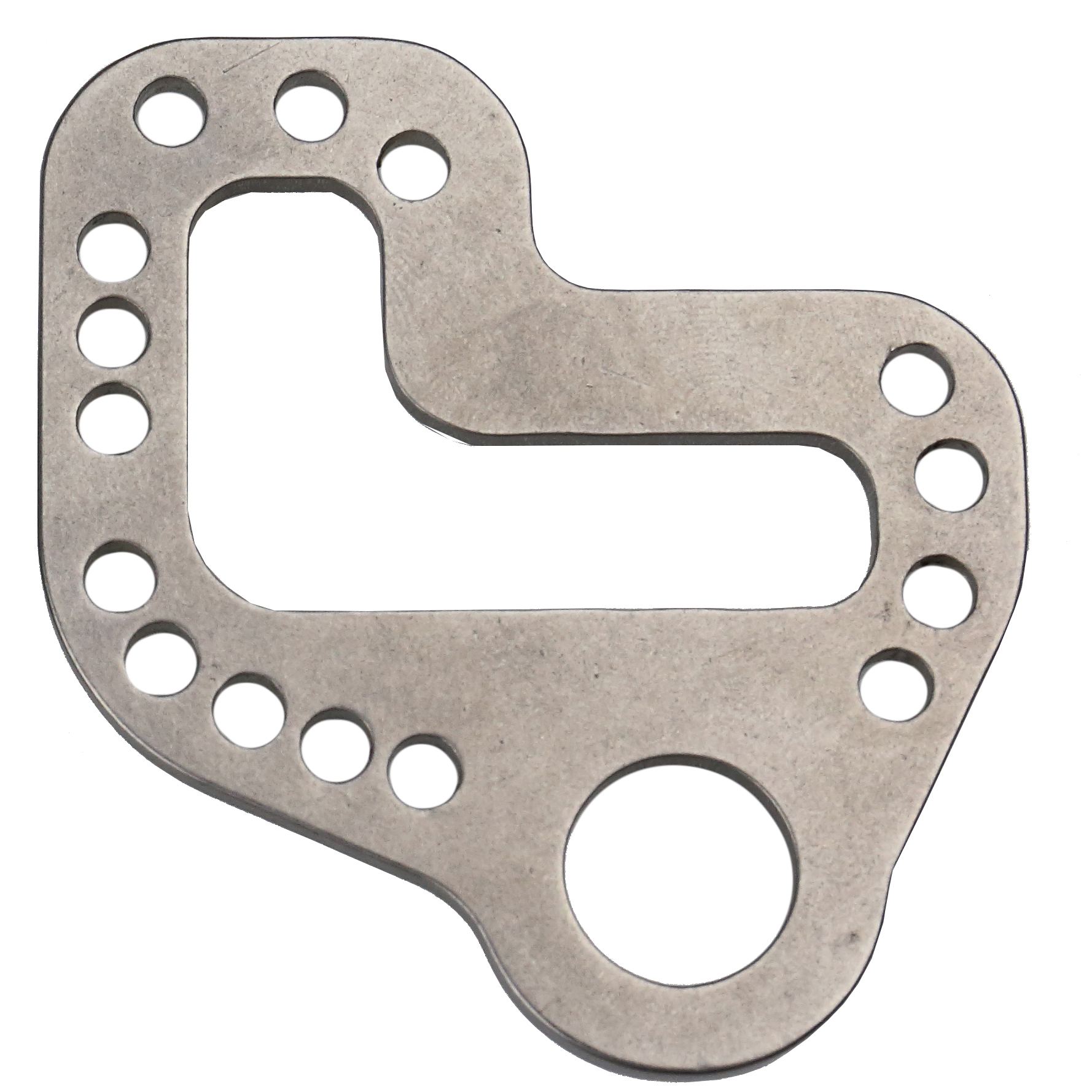

Examples of processing:

Send your samples

and see the result.

Sample form