Cast parts

The main tasks of casting processing include removing surface defects, smoothing and unifying the surface, and blunting sharp edges. Before starting the vibro-abrasive processing process, castings should be trimmed to remove overflows and traces of bringing the alloy to the mold.

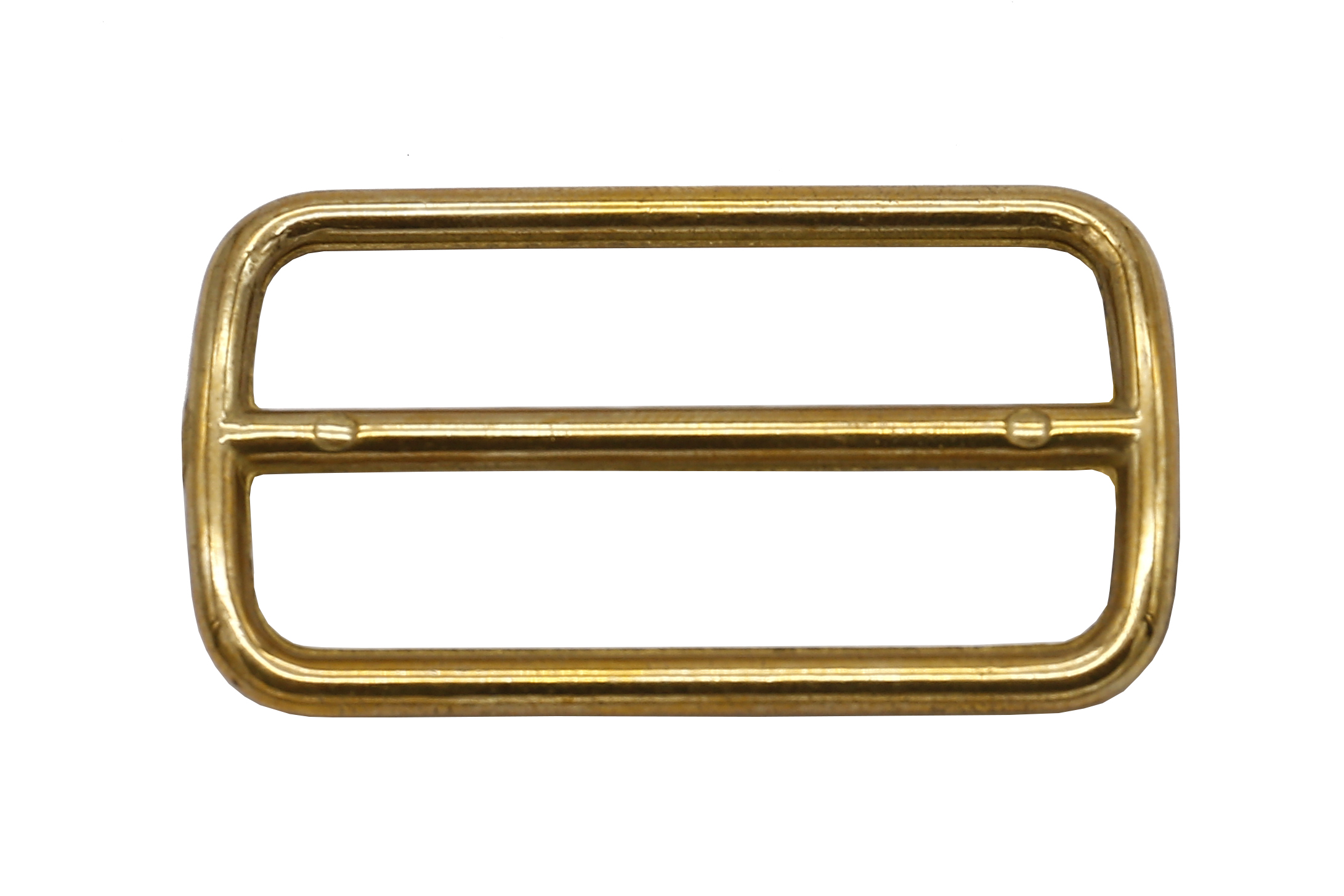

Light metal castings (based on aluminum, zinc, copper, magnesium and their alloys) are mainly clothing and decorative haberdashery, the surfaces of which are prepared for the application of protective and decorative coatings.

In order to smooth the surface, cast parts not exceeding dimensions can be most effectively mass-processed in disc finishing machines, while if we want to obtain polish on the casting surface, a round vibrotory machine will work best.

Examples of processing:

Send your samples

and see the result.

Sample form